End-of-line applications

Efficient and resource-saving packaging production.

Sustainable

When it comes to packing your products efficiently, safely and in a process-controlled manner, it is important to use intelligent and reliable adhesive application systems. The prerequisite for top-quality production on your packaging lines.

Sustainability through innovative and technically highly precise application technology. That's what we do at Baumer hhs. We are a reliable partner, always smart for your needs.

Systematically advantageous

From the adhesive warehouse to the packaging line:

uncompromising quality from a single source.

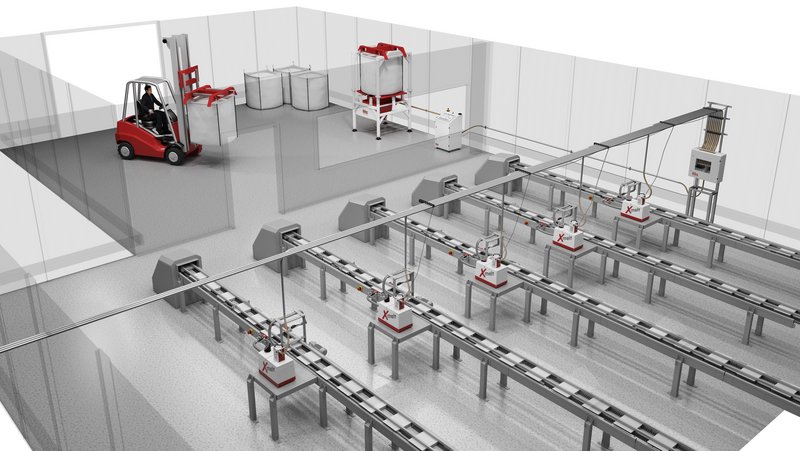

Our entire system is designed and optimized for the final packaging process: All modules work together seamlessly from material delivery to the quality-controlled end product - so you can benefit from a multitude of advantages.

Modular technology for a perfect system

Automate your adhesive supply in the final packaging process completely or partially by integrating individual Baumer hhs modules into existing production lines. The bidirectional communication of the central supply between the components makes your overall system safe, sustainable and reliable.

Take advantage of our three system integration levels - go, evo and pro - depending on the task.

Your personal contact will be happy to advise you.

Baumer hhs offers you the right solution

Baumer hhs provides reliable and cost-effective solutions for all end-of-line packaging requirements.

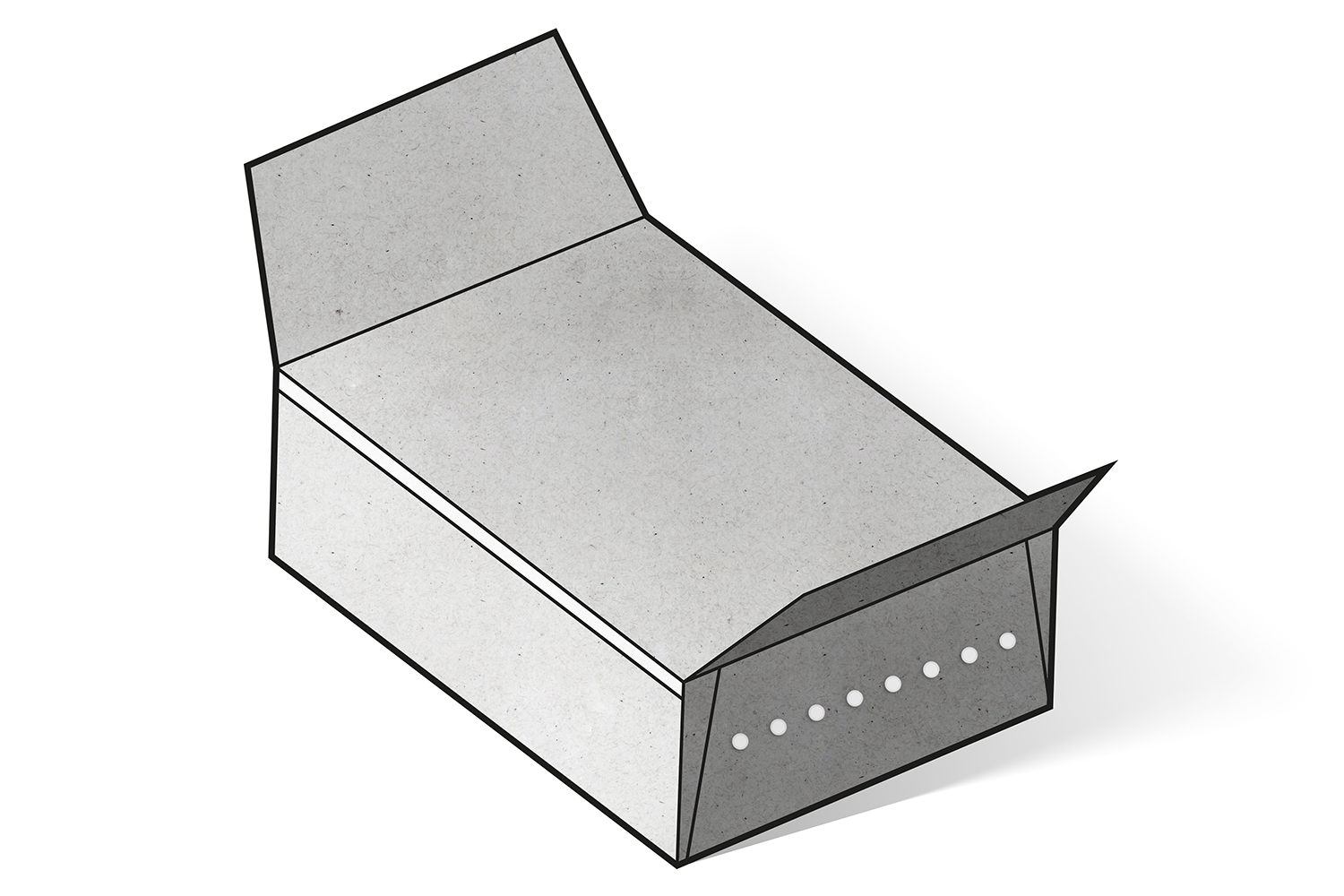

Retail packaging

Food and pharmaceutical products are usually securely sealed with adhesive in cartoners. This protects the products from transport damage and manipulation. Baumer hhs supplies the technology to ensure this product protection.

The electric tesla application heads apply hot melt in a resource-saving manner.

- High closing force for precise application.

- Reduces machine pollution.

- Short and long nozzle.

- Long service life. Up to 1 billion switching cycles. Up to 600Hz clock frequency in dot application.

- Large selection of adhesives which can be processed.

- The valves are integrated in the packaging machine

They are controlled via the machine control (PLC).

Correct adhesive application can be monitored with the HLT-300 hot melt sensor.

- The sensor is evaluated via the machine control (PLC).

- Reliable hot melt monitoring.

- 100% glue monitoring.

- Integrated light barrier function.

The electric tesla application heads apply hot melt in a resource-saving manner.

- High closing force for precise application.

- Reduces machine pollution.

- Short and long nozzle.

- Long service life. Up to 1 billion switching cycles. Up to 600Hz clock frequency in dot application.

- Large selection of adhesives which can be processed.

- The valves are integrated in the packaging machine

They are controlled via the machine control (PLC).

Correct adhesive application can be monitored with the HLT-300 hot melt sensor.

- The sensor is evaluated via the machine control (PLC).

- Reliable hot melt monitoring.

- 100% glue monitoring.

- Integrated light barrier function.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

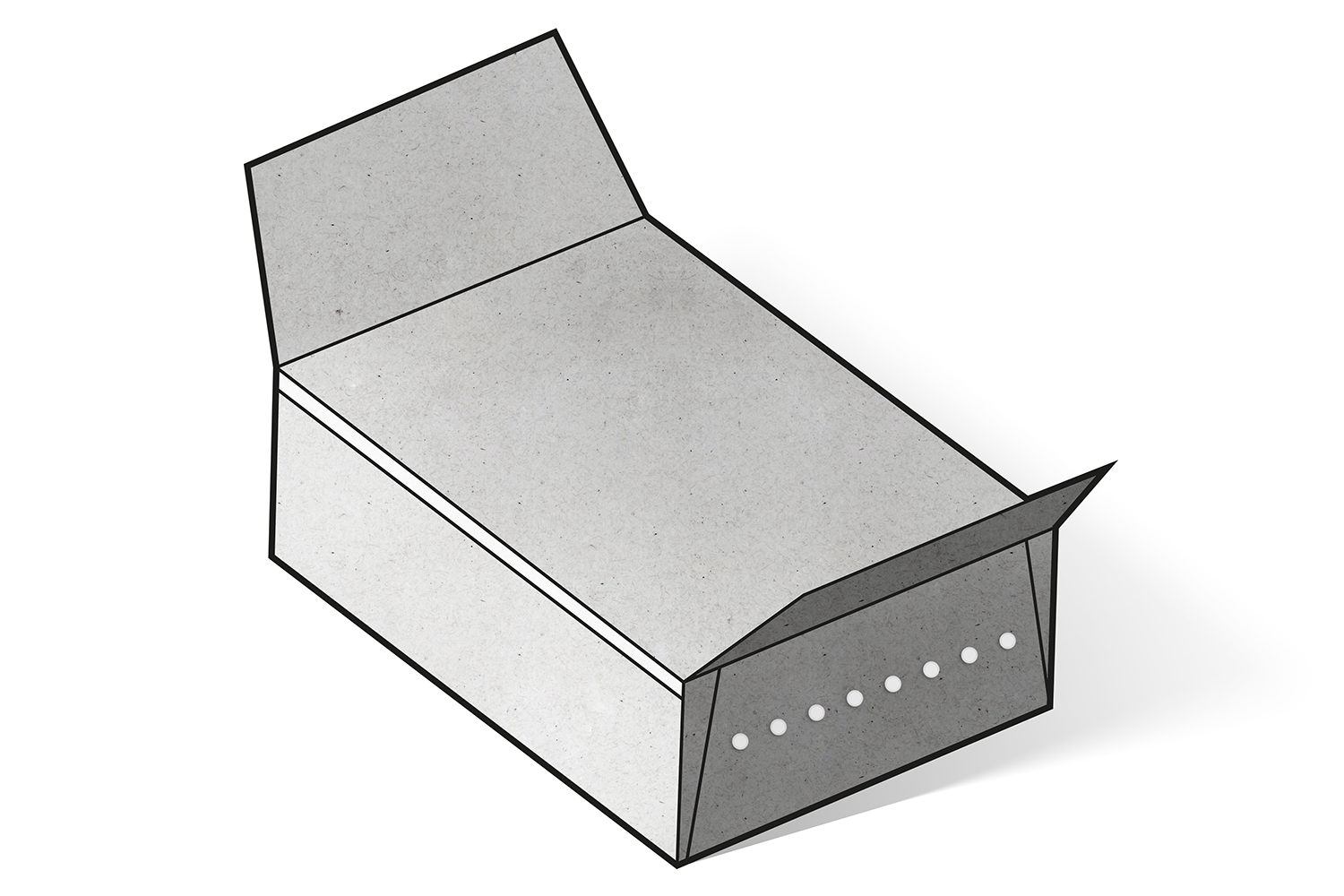

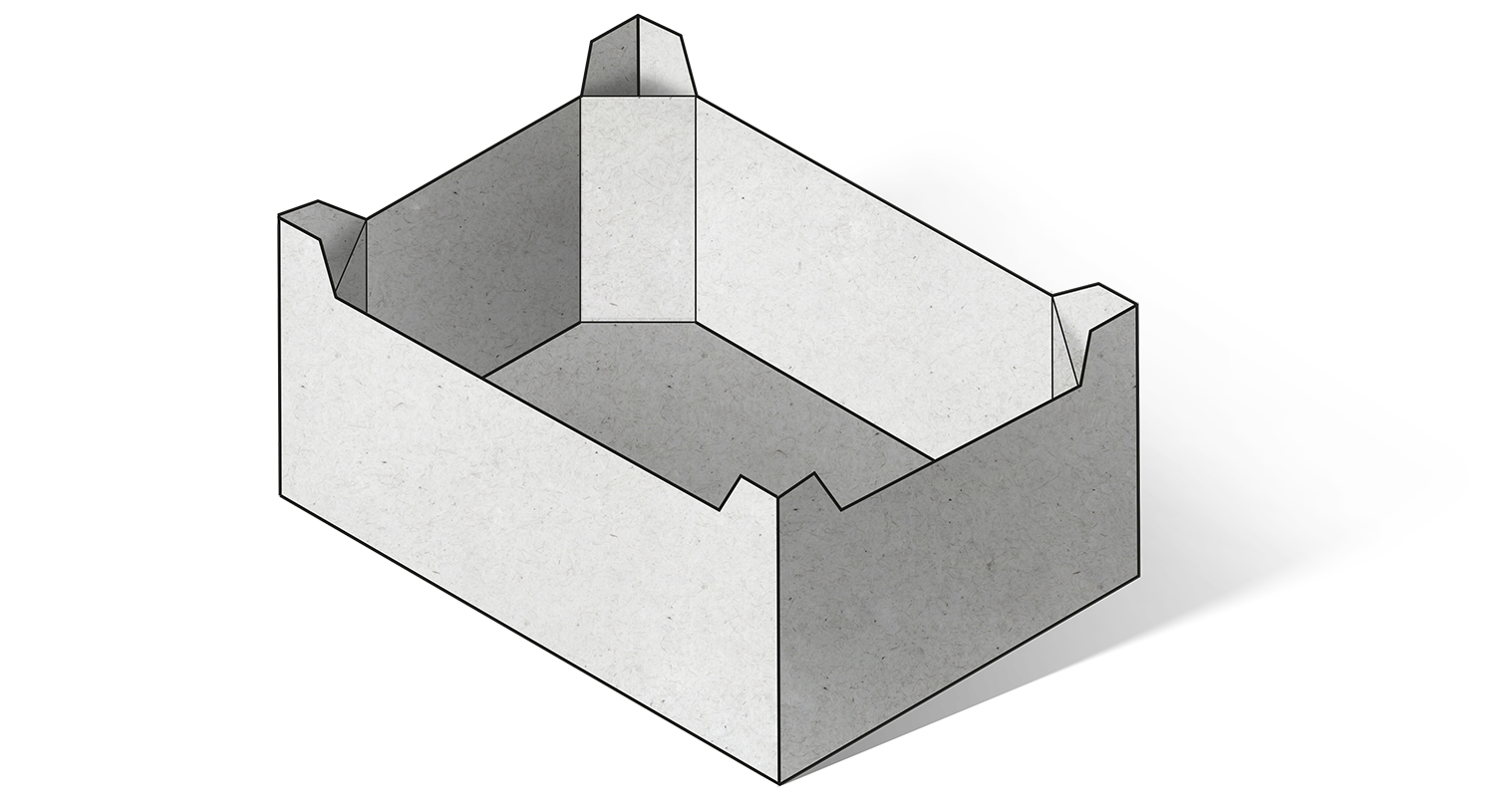

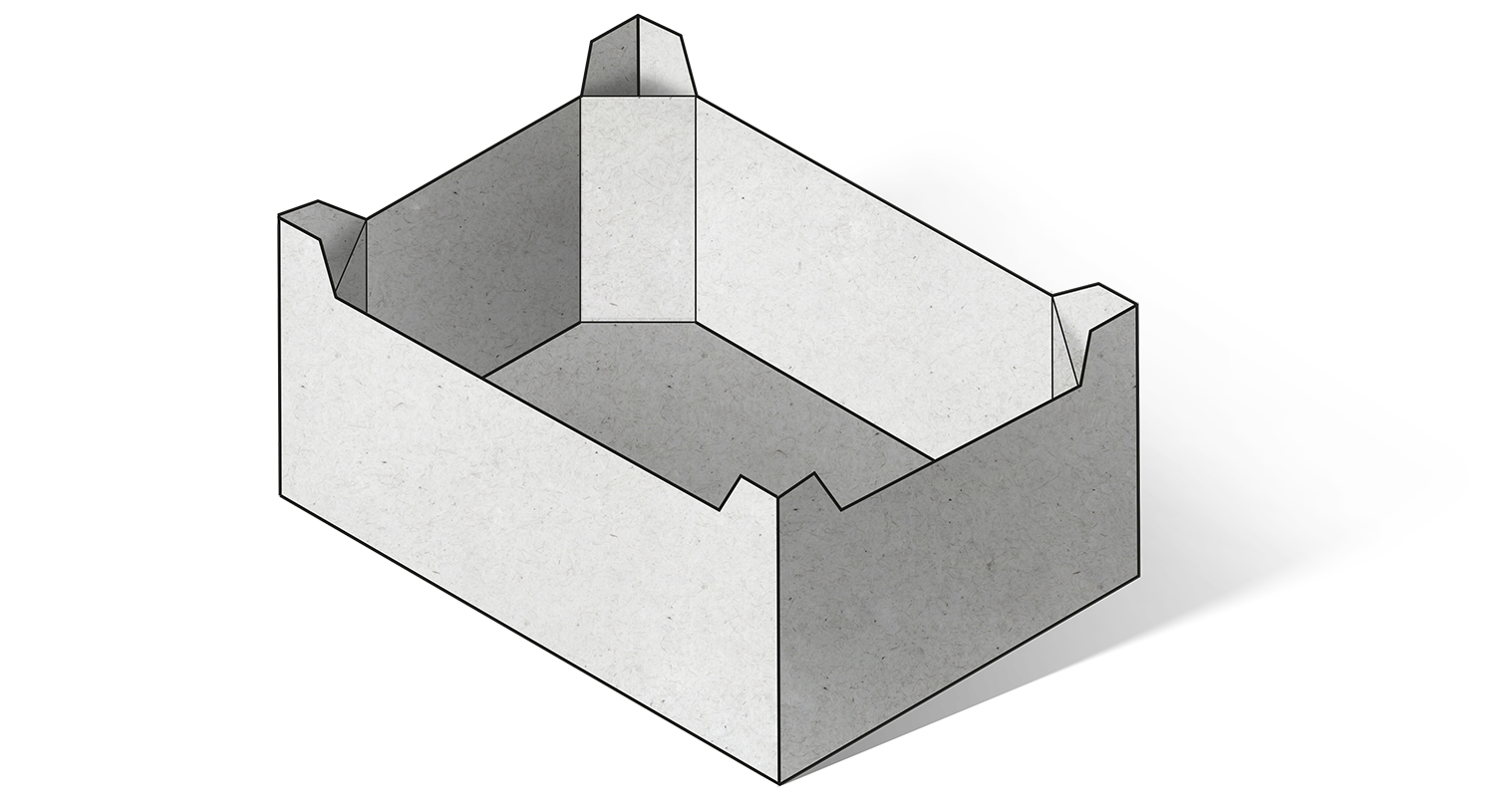

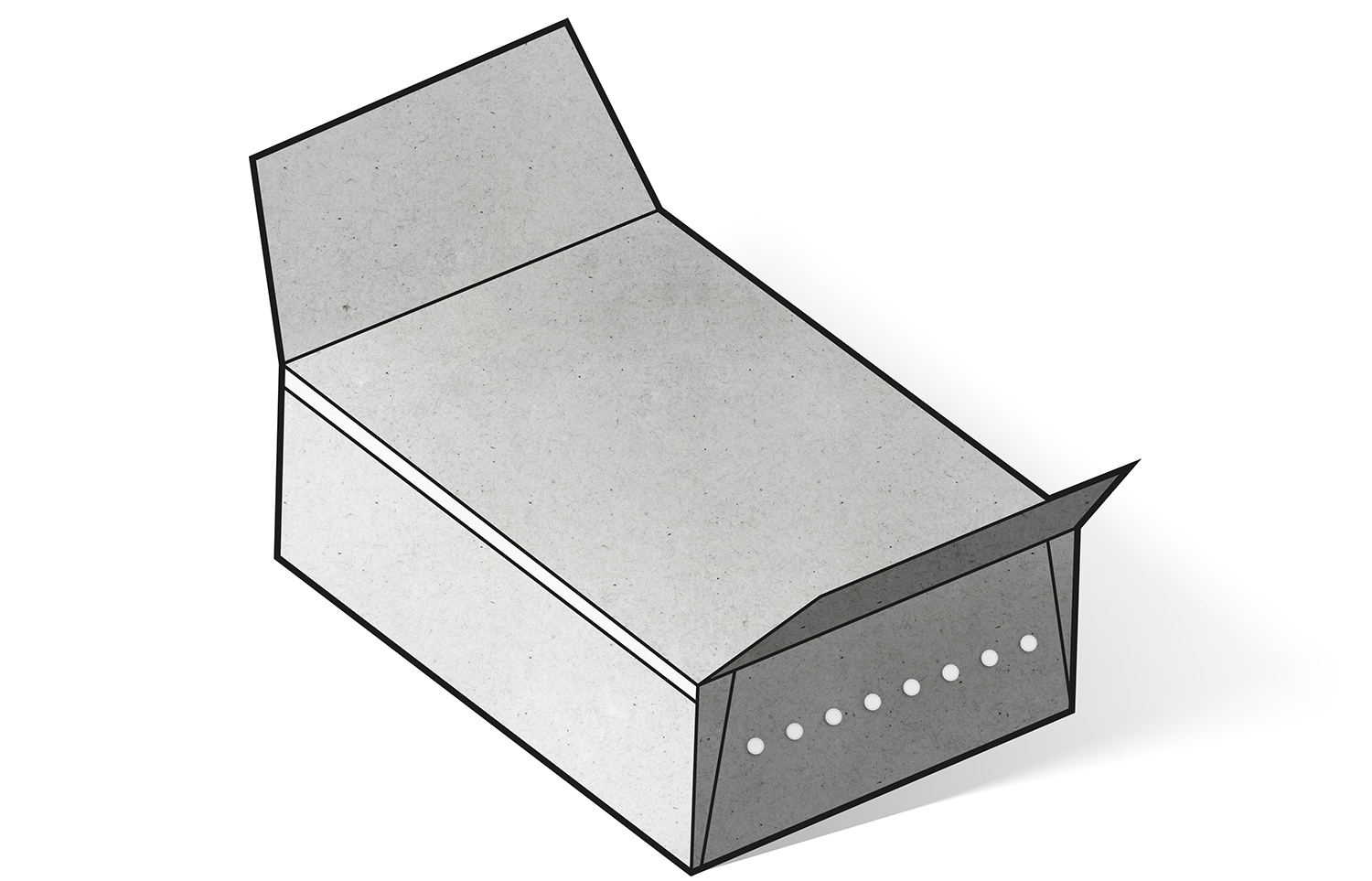

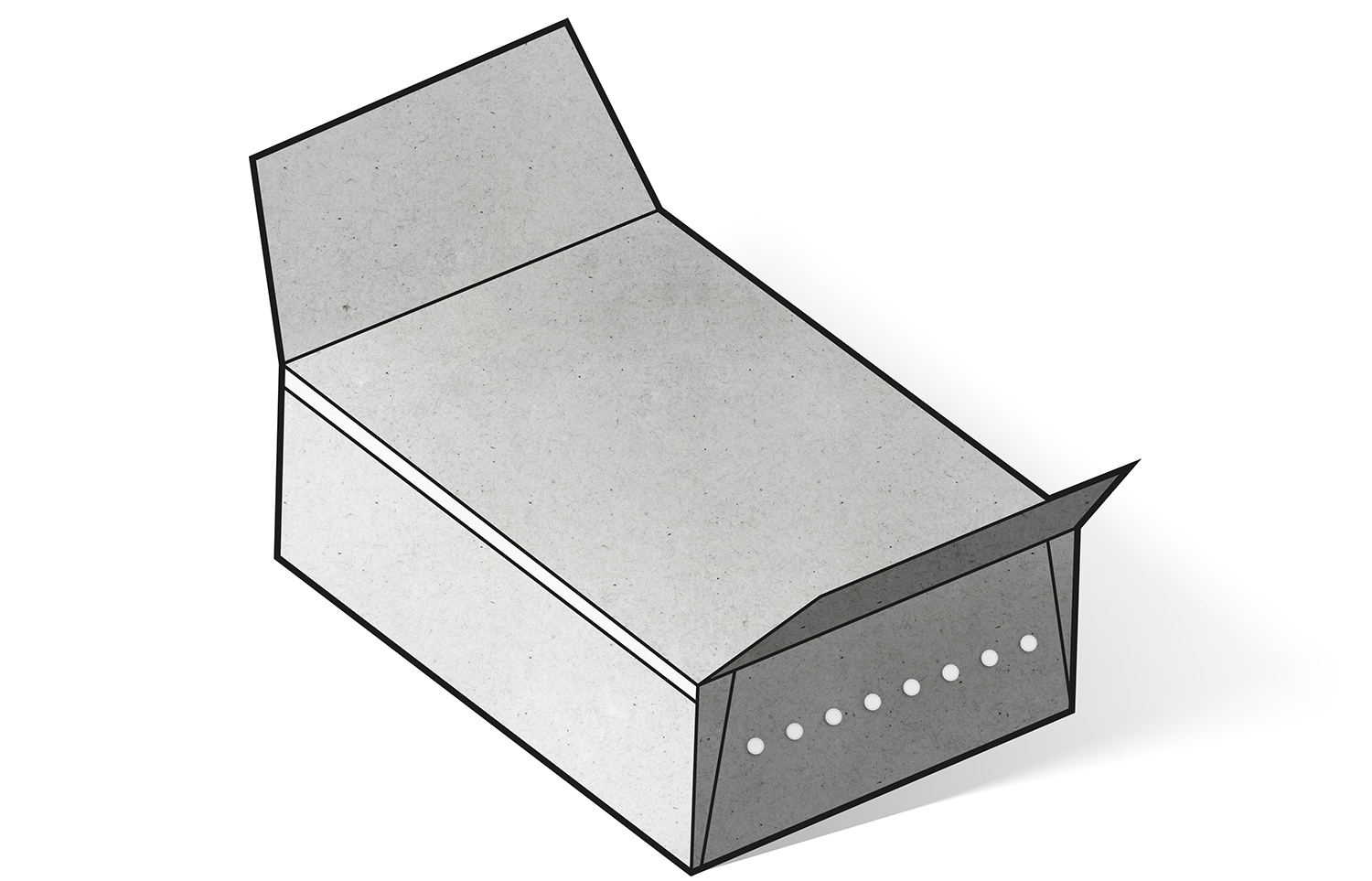

Tray packaging

For products such as fruit and vegetables or beverage packaging, erected cartons without a lid are mostly used. With Baumer hhs solutions, you can rely on 100% stability and packaging reliability in your packaging line. Inline bonding is integrated into the packaging process, which erects the carton blank into a tray by means of adhesive flap gluing.

The electric tesla application heads apply hot melt in a resource-saving manner.

- The valves are integrated in the packaging machine

- They are controlled via the machine control (PLC).

The electric tesla application heads apply hot melt in a resource-saving manner.

- The valves are integrated in the packaging machine

- They are controlled via the machine control (PLC).

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

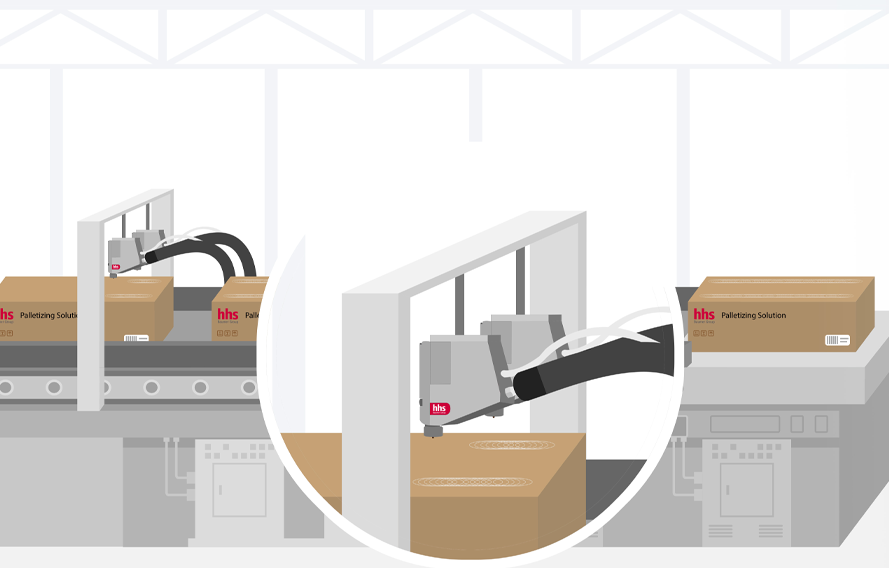

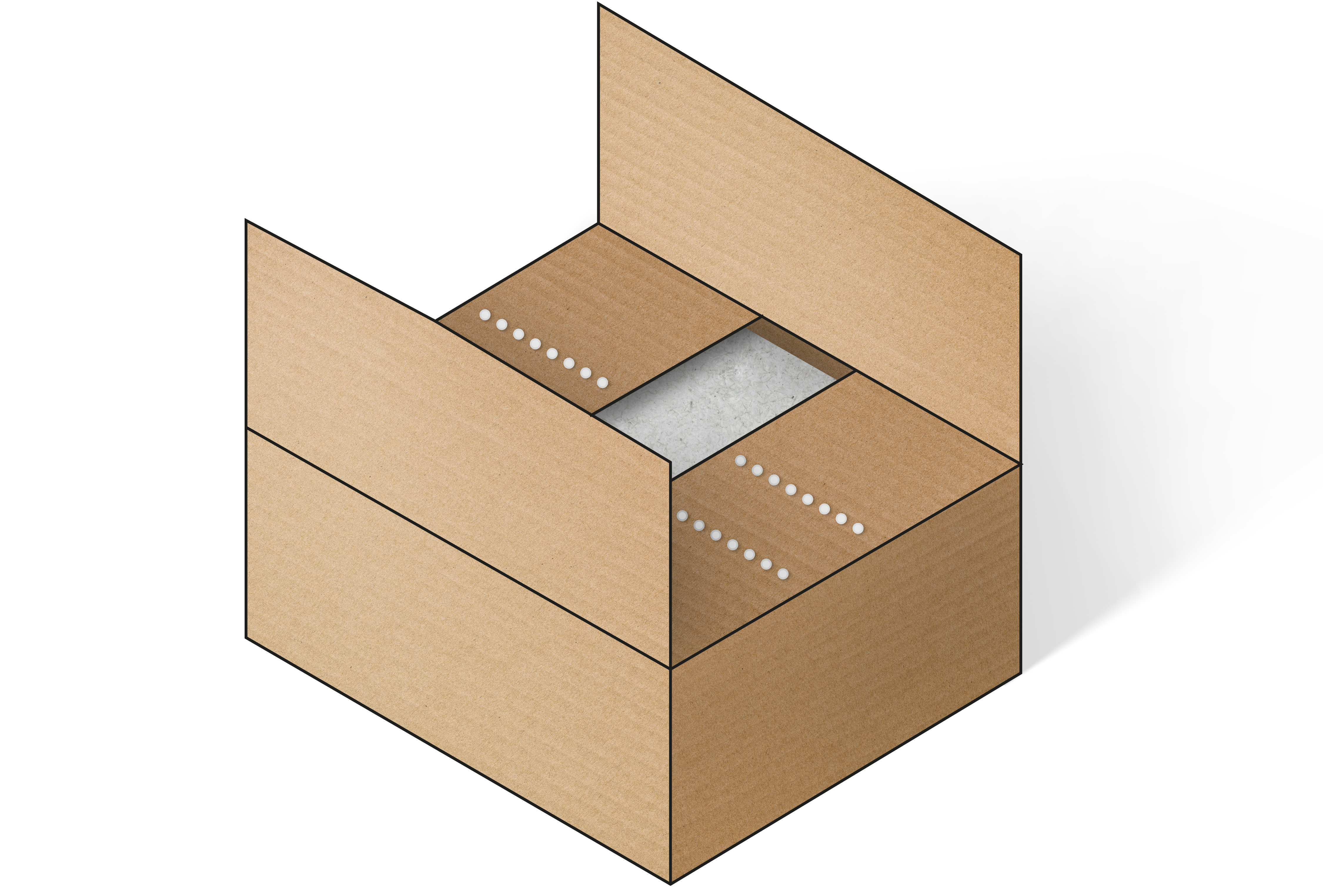

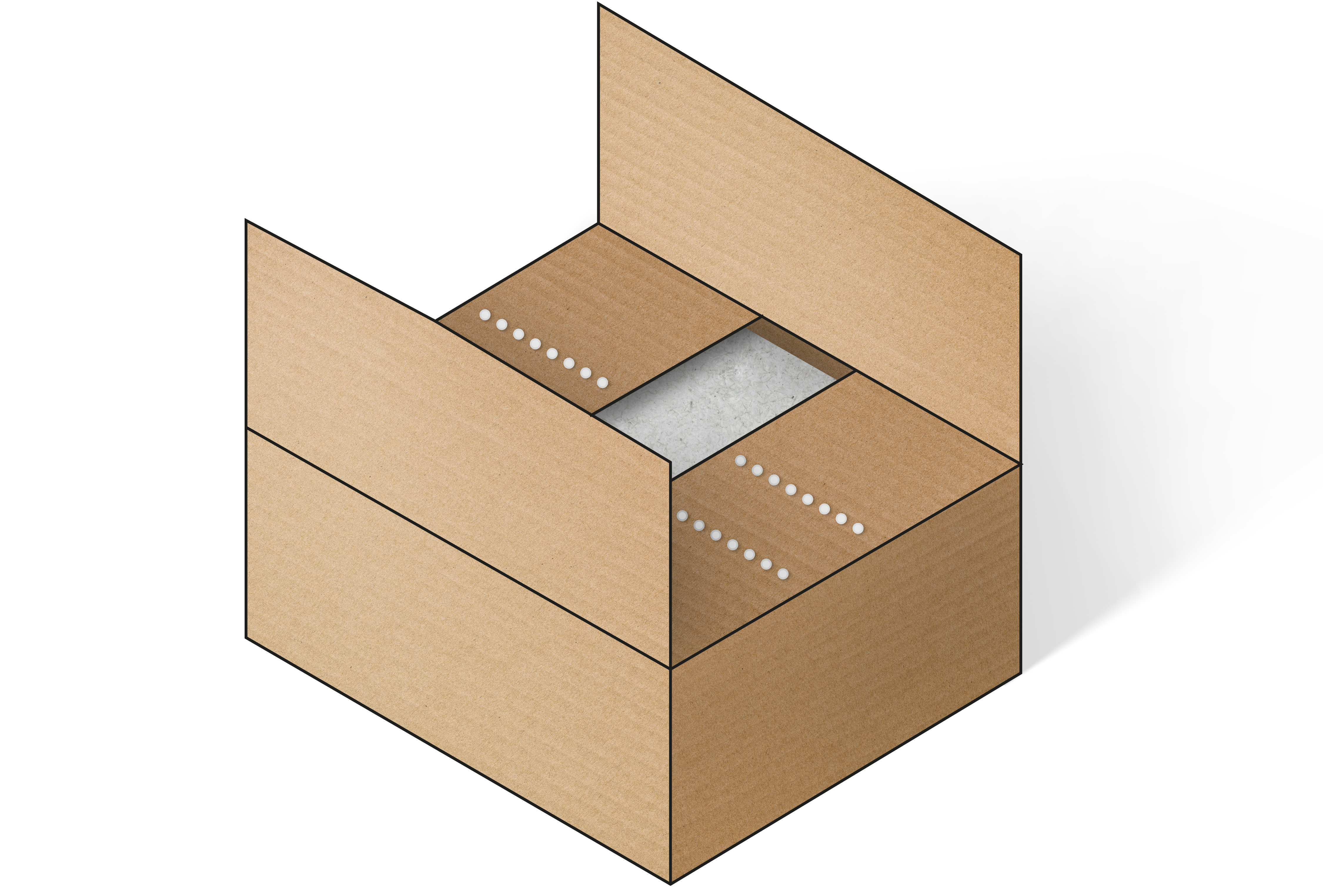

Carton closure

Transport boxes made of corrugated board are usually used to transport goods. These offer reliable protection, are inexpensive and recyclable.

Depending on the machine configuration, different application heads can be used, which are controlled directly via the PLC.

- The tesla electric application head is used when the distance to the product is small.

- For larger distances or higher adhesive viscosities, the pneumatic aerto valve is used.

- Both valve types offer the possibility of using dot application to save up to 50% adhesive.

Depending on the machine configuration, different application heads can be used, which are controlled directly via the PLC.

- The tesla electric application head is used when the distance to the product is small.

- For larger distances or higher adhesive viscosities, the pneumatic aerto valve is used.

- Both valve types offer the possibility of using dot application to save up to 50% adhesive.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

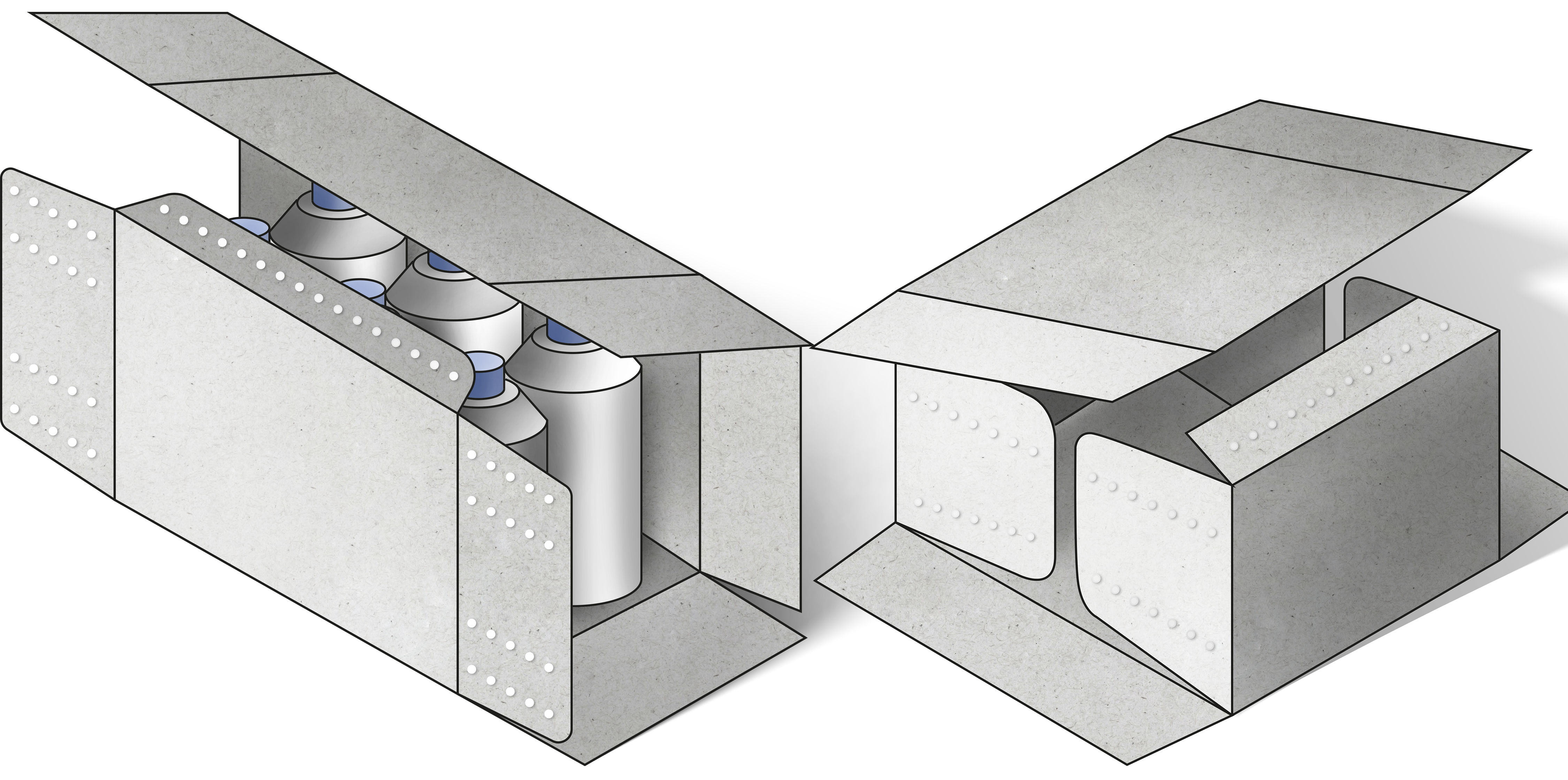

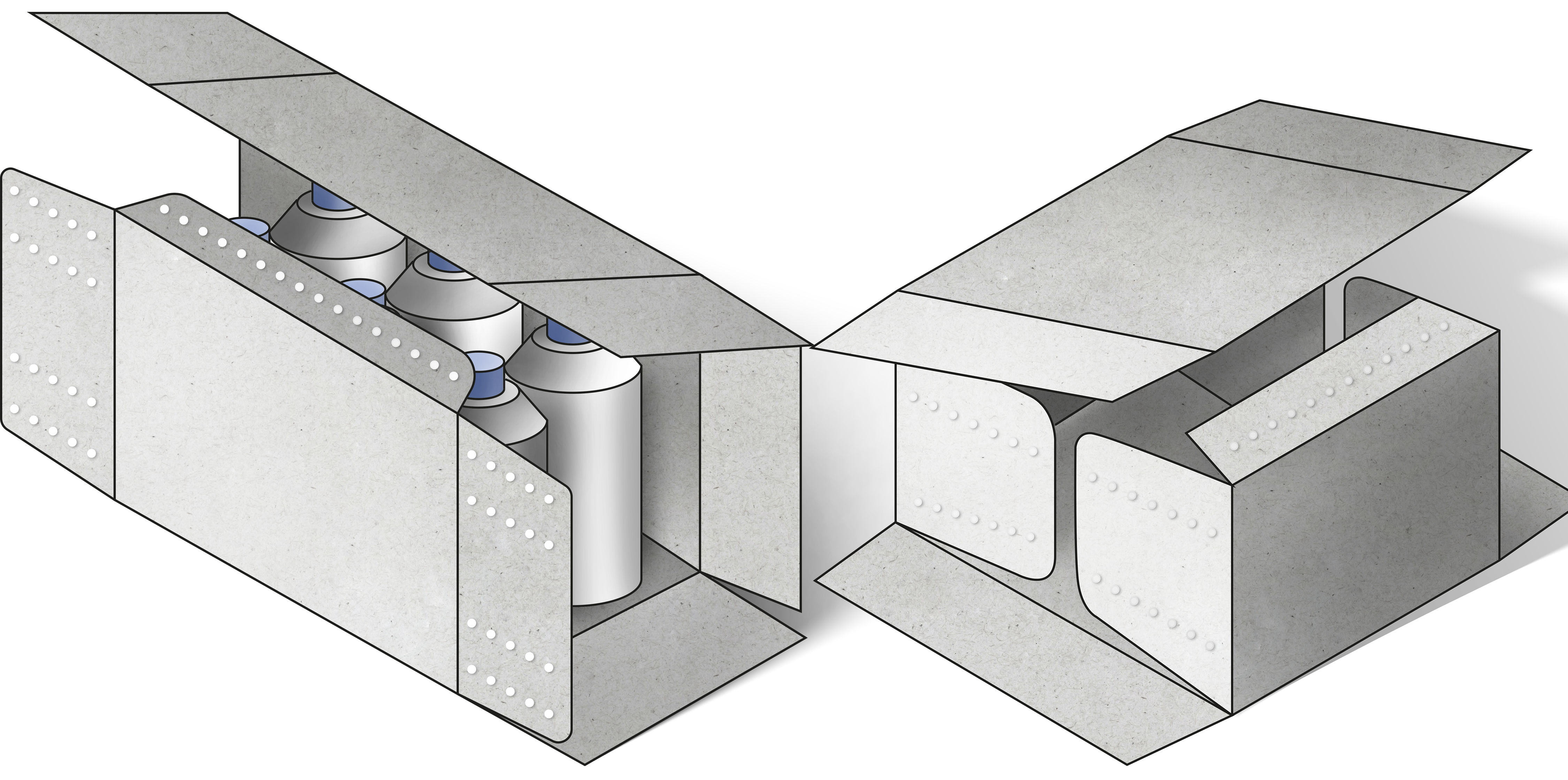

Wrap around

With wrap around packaging, a box is formed from a carton blank and filled in one go. Baumer hhs technology reliably ensures lengthwise and crosswise gluing in the packaging process. With dot application, your packaging is perfectly sealed, easy-to-open and glued cost-effectively.

Depending on the machine configuration, different application heads can be used, which are controlled directly via the PLC.

- The tesla electric application head is used when the distance to the product is small.

- High closing force for precise application.

- Reduces machine pollution.

- Short and long nozzle.

- For larger distances or higher adhesive viscosities, the pneumatic aerto valve is used.

- Both valves offer the possibility of using dot application to save adhesive.

Der korrekte Auftrag des Klebstoffes kann mit dem Heißleim Sensor HLT-300 überwacht werden.

- Die Auswertung des Sensors erfolgt über die Maschinensteuerung (SPS).

- Zuverlässige Heißleimüberwachung.

- 100%-ige Klebstoffüberwachung.

- Integrierte Lichtschrankenfunktion.

Depending on the machine configuration, different application heads can be used, which are controlled directly via the PLC.

- The tesla electric application head is used when the distance to the product is small.

- High closing force for precise application.

- Reduces machine pollution.

- Short and long nozzle.

- For larger distances or higher adhesive viscosities, the pneumatic aerto valve is used.

- Both valves offer the possibility of using dot application to save adhesive.

Der korrekte Auftrag des Klebstoffes kann mit dem Heißleim Sensor HLT-300 überwacht werden.

- Die Auswertung des Sensors erfolgt über die Maschinensteuerung (SPS).

- Zuverlässige Heißleimüberwachung.

- 100%-ige Klebstoffüberwachung.

- Integrierte Lichtschrankenfunktion.

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Pallet stabilization

Secure your transport packaging against slipping by applying pressure-sensitive adhesive. This securely fixes each position on the pallet, even without film and reduces the use of plastics and facilitates handling in transport and in the warehouse. (Read more)

Pallet securing with the pneumatic hot melt head HM-500.

- Controlled via the machine control (PLC).

- The adhesive is applied to the transport packaging as a spray application or in spiral shapes

Pallet securing with the pneumatic hot melt head HM-500.

- Controlled via the machine control (PLC).

- The adhesive is applied to the transport packaging as a spray application or in spiral shapes

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

Tamper evidence product protection

According to EU Directive 2011/62/EU, prescription drugs must be protected against tampering. Consumers should be protected from counterfeit medicines. Opened packaging can be identified by damage to the packaging at the point of delivery (pharmacy, hospital,...).

Baumer hhs technology provides solutions that implement the EU directive and conform to normative specifications.

Conformity with DIN/EN-ISO 21976.

Baumer hhs not only offers hot melt solutions, but also solutions which combine hot melt and cold glue that enable a much higher level of protection.

This enables pharmacists to achieve a new level of product protection.

The electric tesla application heads apply hot melt in a resource-saving manner.

- The valves are integrated in the packaging machine

- They are controlled via the machine control (PLC)

In addition, the DDL-500 electrical cold glue valves can provide greater protection

- Integration of the compact cold glue valves in the packaging machine

- Control via a Baumer hhs control unit

Correct application adhesive can be monitored with the HLT-300 hot melt sensor.

- The sensor is evaluated via the machine control (PLC)

- Reliable hot melt monitoring

- 100% glue monitoring

- Integrated light barrier function

The additional cold glue application is monitored with ULT-300 sensors.

- Evaluation is performed via the PLC machine control or via a Baumer hhs control unit

The electric tesla application heads apply hot melt in a resource-saving manner.

- The valves are integrated in the packaging machine

- They are controlled via the machine control (PLC)

In addition, the DDL-500 electrical cold glue valves can provide greater protection

- Integration of the compact cold glue valves in the packaging machine

- Control via a Baumer hhs control unit

Correct application adhesive can be monitored with the HLT-300 hot melt sensor.

- The sensor is evaluated via the machine control (PLC)

- Reliable hot melt monitoring

- 100% glue monitoring

- Integrated light barrier function

The additional cold glue application is monitored with ULT-300 sensors.

- Evaluation is performed via the PLC machine control or via a Baumer hhs control unit

Zur Anzeige des Klick-Modells nutzen Sie gerne unsere Desktop-Version.

dot box kit

Baumer hhs provides you with a complete system with which you can easily make the switch to dot application without any initial costs. Our dot box kit contains everything you need to convert your packaging line in less than two hours. You save adhesive immediately and thus counteract the cost explosion in material procurement.

Guaranteed ROI in less than 3 months.

See for yourself.

Watch this video to see how easy the intergation into your packaging line really is.

Palletizing Solution

Effective load securing is crucial for the protection of goods, compliance with legal regulations, logistics efficiency and the prevention of accidents. Baumer hhs presents an innovative solution for securing pallets and transport cartons in an environmentally friendly way - the Palletizing Solution, which uses anti-slip adhesive instead of plastic foils.

How much foil can be saved with the Baumer hhs Palletizing Solution?

- 100 % savings in internal transport

- 100 % savings in external, closed transport

- 65-80 % savings in external standard transport

Sustainability

Resource-saving for more sustainability

50% and more adhesive savings through dot application

50% energy saving

Melt-on-demand technology

Durable, low-maintenance valve technology

Developed for better safety

Central, automated adhesive supply prevents burns

Adhesive storage outside sensitive production areas

No adhesive fumes

Over-temperature switch prevents fire hazard

Employee protection in the workplace

Safety