Volume 05

The power of less: Reducing adhesives, maximising efficiency

In our Eco Talks series, various people in management positions at Baumer hhs get an opportunity to share their personal insights on the subject of sustainability. In exclusive interviews, they shed light on Baumer hhs's past and ongoing steps to promote sustainability, and they explain exactly how our innovative solutions help customers to minimise their ecological footprint while making production processes more efficient. Eco Talks – Inspiring insight into sustainable innovation and responsibility.

Sustainability increasingly is considered a measure of innovation in the packaging industry. In the debate surrounding materials and recycling, one critical aspect often gets overlooked: the adhesives. But even small changes in adhesive application can have a tremendous impact on saving resources, CO₂ footprint, production costs, and recyclability. In our interview with Andreas Brandt, Marketing Manager at Baumer hhs, we soon learned that if you want to act sustainably, you have to be able to think in millilitres. Our editor Florian Lemke spoke with him about precision application, durable equipment and why intelligent adhesive application is an underestimated lever for greater efficiency and responsibility.

Florian Lemke: Mr. Brandt, we’re hearing a lot about sustainability in the packaging industry. But most of the talk is about materials, less about adhesives. Are they even relevant?

Andreas Brandt: They most certainly are. Though adhesives are often treated as a secondary factor in packaging production, they play a decisive role. And you have to remember: Glue is applied millions of times a day in a packaging business. At that level, saving just one gram per unit adds up to a significant reduction in resource consumption, not to mention the cost effect.

Florian Lemke: Why exactly is reducing adhesive use so critical to sustainability? I mean it’s not just about the cost you mentioned.

Andreas Brandt: The economic aspect naturally is important. Using less adhesive means lower material costs. But the point is that each gram of glue we don’t need, doesn’t have to be produced in the first place. And that has a big impact on improving sustainability, because manufacturing adhesives consumes raw materials and energy, and generates CO₂ emissions. The less we use, the less we transport – often over long distances – and the less we ultimately have to dispose of. It’s easy to underestimate the ecological burden of even a small amount of glue. Our systems help to reduce that burden, without compromising on quality in the given application.

Florian Lemke: How does Baumer hhs reduce adhesive consumption?

Andreas Brandt: For many years now, we have been concentrating on solutions for precise, resource-saving gluing. I’m talking about our innovative application modes with which we can dispense lower quantities of adhesive with very high precision, while maintaining the same high level of quality. Our “dotting” and “stitching” modes are an example.

Florian Lemke: That sounds like shop talk, how exactly do these gluing modes work?

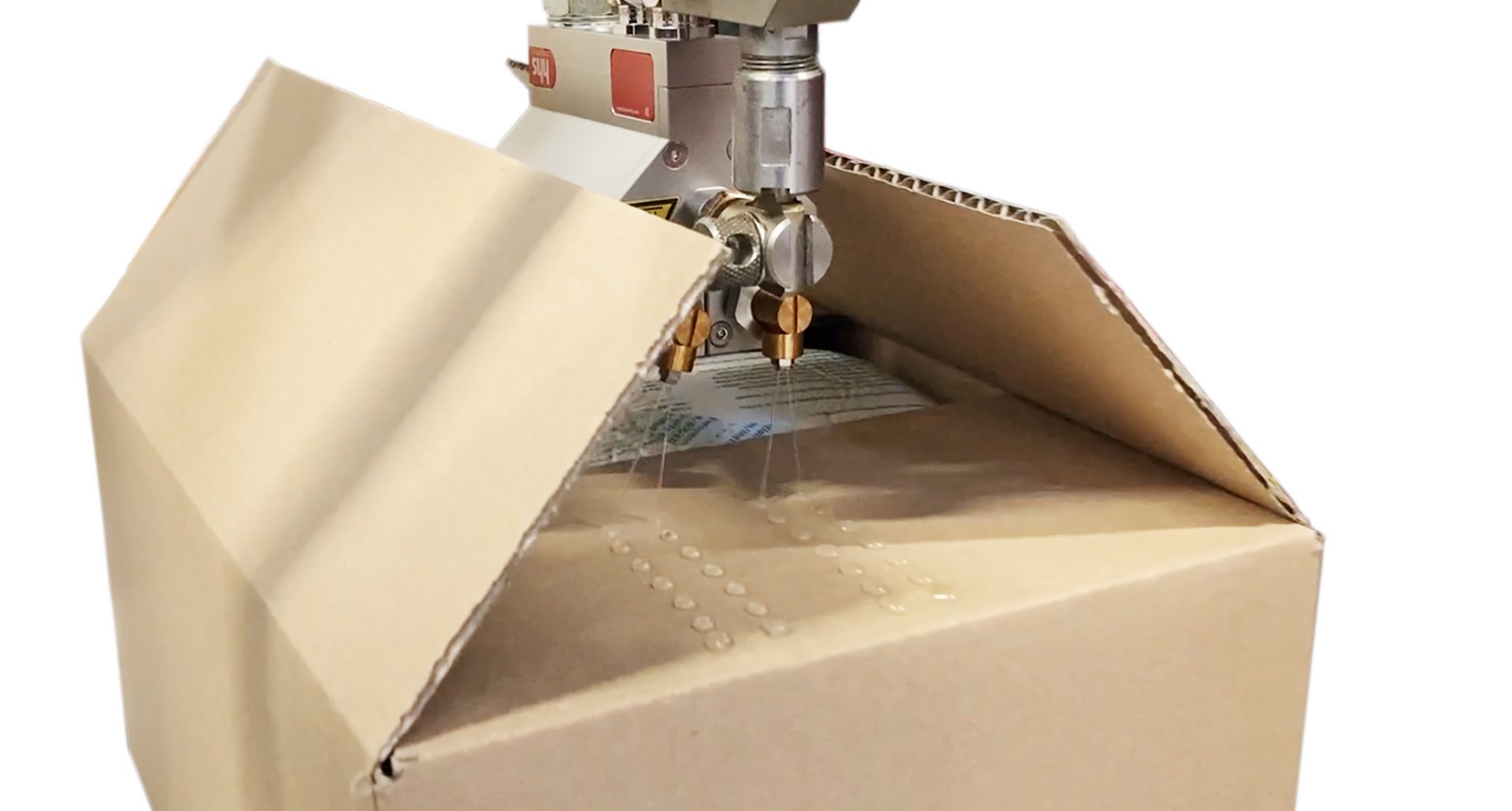

Andreas Brandt: In the past – and even today in many cases – adhesive was applied as a continuous bead of glue. In other words, in an unbroken line like toothpaste out of a tube. By nature, this method uses more glue than is strictly necessary for stable joints. Instead, our systems apply either short segments or discrete dots of glue. Between these points of application is a gap of “open space”, which however does not weaken the glued joint, because the glue spreads out when the surfaces are pressed together, resulting in an equally strong, sometimes even better, bond.

Florian Lemke: So the result is even better?

Andreas Brandt: In many cases, yes. The trick is that we take advantage of the physical properties of the glue: its viscosity, flow behaviour, curing. For example, dot mode dispenses tiny dots of glue right where they are needed. Stitching mode breaks up the lines of glue into short segments, which is ideal particularly for gluing corrugated board. These methods reduce material consumption significantly, often by up to 50 percent. And that is not a marketing claim. It’s a realistic goal that our customers regularly achieve in practice.

Florian Lemke: Is this technology already established among customers?

Andreas Brandt: Yes it is. Many of our customers are using it, especially those who focus on sustainability and cost-efficiency. But we still see huge potential for expanding the use of this technology. Some producers are still reticent, because they think dot application could cause adhesion problems. But the opposite is true if things are done right, and that’s why intense customer support and practice tests are so important to us.

Florian Lemke: Let’s talk about the actual equipment. The CorrBox Solution is one of your flagship products. What makes it so special?

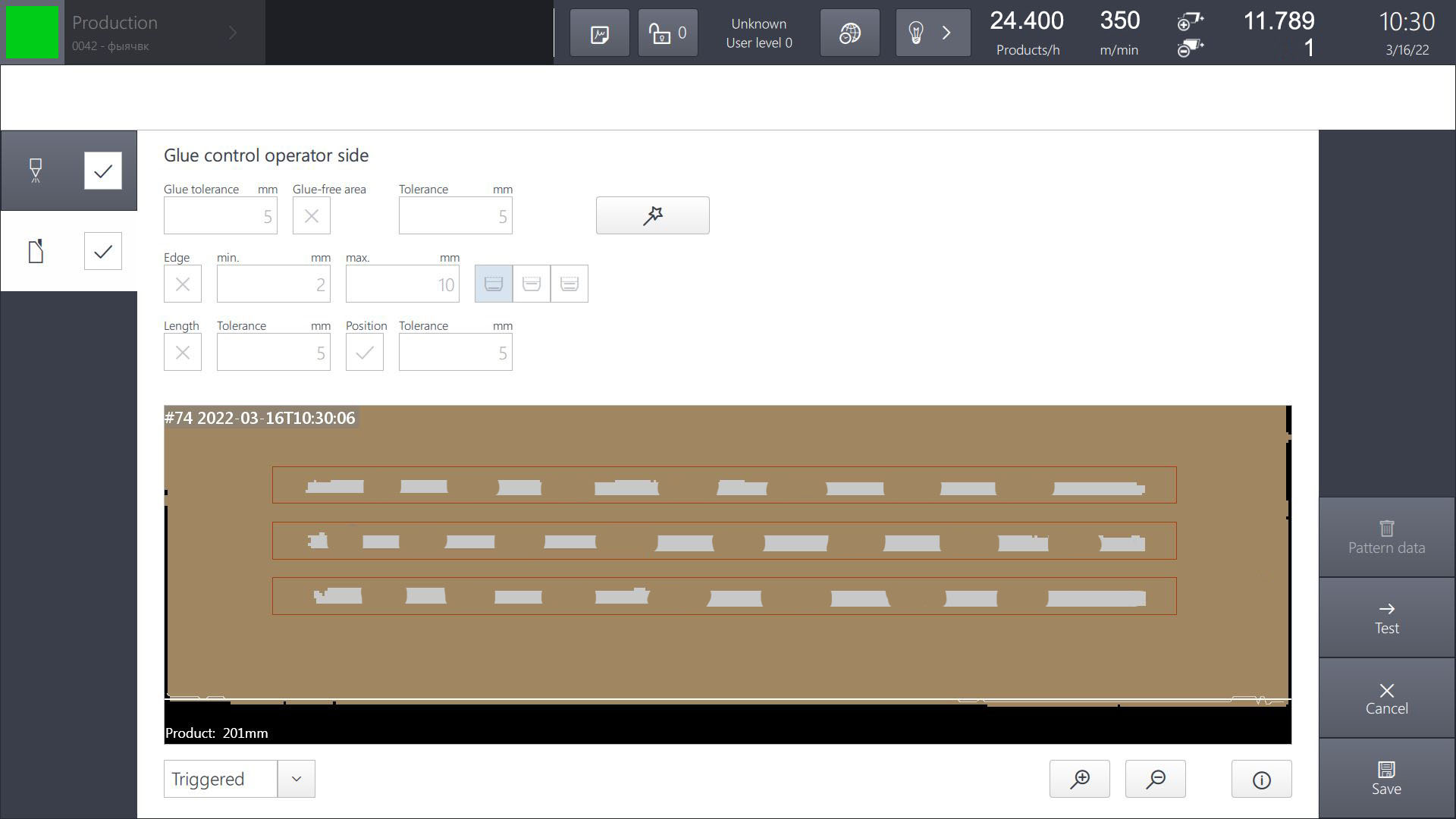

Andreas Brandt: CorrBox Solution is a modular, complete solution for gluing and quality assurance in corrugated board converting. It combines precision application equipment with intelligent controller quality control systems. The heart of the system is the Glue Save Mode, a software function that regulates adhesive application. The operator enters the percentage of glue reduction in the controller, and the system re-sets automatically. Consumption gets reduced with just one click.

Florian Lemke: And quality doesn’t suffer?

Andreas Brandt: On the contrary, as independent studies by the PTS (research and service institute of the German paper industry) have confirmed. In addition, customers report that dispensing glue more strategically has even improved their glued joints, because too much adhesive can be just as bad as too little. It can ooze out, damage surfaces or take unnecessarily long to dry. Less is often more in this case, as long as it is controlled

Florian Lemke: Another subject that easily gets overlooked: the longevity of the equipment. How does Baumer hhs approach it?

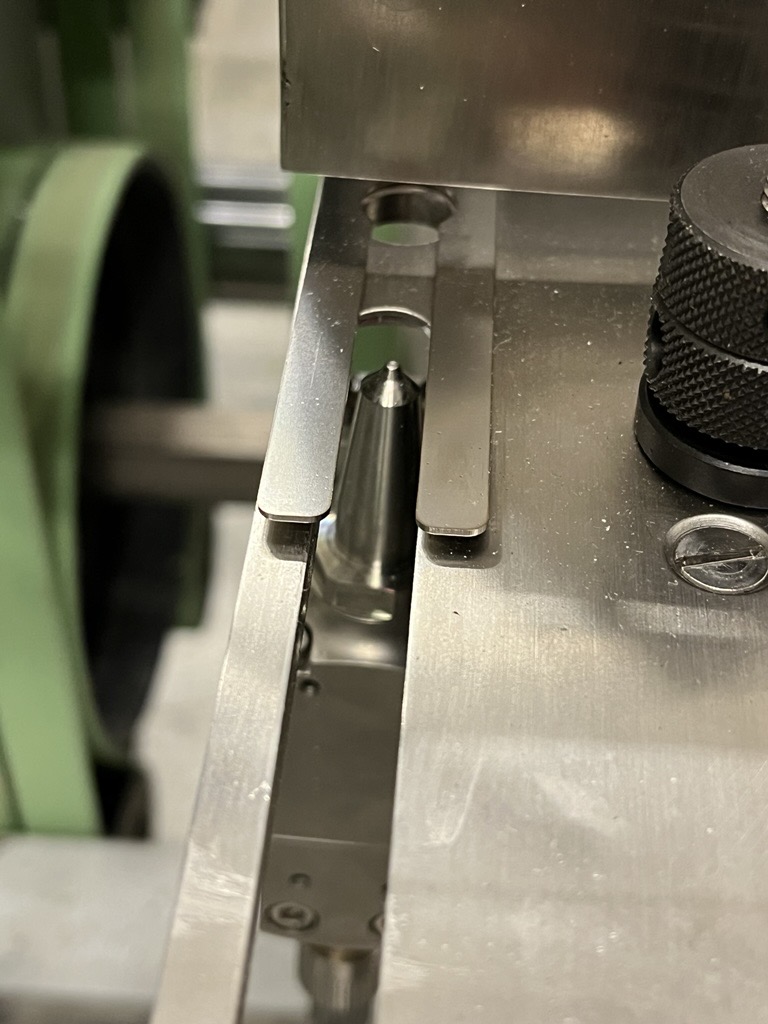

Andreas Brandt: Durability is a very important aspect of sustainability. A long-lived system not only saves money, it also conserves resources and energy, and reduces CO₂-emissions. Take our PX 1000 application head for instance. It is one of our high-end heads for applying cold glue. It was designed for maximum durability and can withstand hundreds of millions of cycles, depending on the application. And I mean in real, high-speed production lines, not under laboratory conditions. The same is true of all our application heads.

Florian Lemke: What makes the PX 1000 and all the other heads so durable?

Andreas Brandt: As a pioneer of electric application heads for cold glue and hot melt application, Baumer hhs is an innovation leader in this technology, which is distinguished by its low wear and very high precision.

Added to this are the combined advantages of clever design, premium materials and precision manufacturing. The internal components are designed to function for years under high load and intense use. The housing is heavy-duty, the sealing systems are low-wear. In short, the equipment is maintenance friendly and durable, which translates into real added value in terms of sustainability.

Florian Lemke: Is it an economic advantage as well?

Andreas Brandt: Yes, absolutely! Because both count in practice: If you reduce both glue consumption and maintenance intervals, you can significantly cut the total cost of production. And without compromising on quality in any way – on the contrary.

Florian Lemke: How do customers respond to these arguments?

Andreas Brandt: Very positively, especially when we demonstrate the technical advantages in a real production environment. In our experience, sustainability is not an end in itself for many of our customers, but part of an overall optimization process. And that is exactly what we provide with our solutions.

Florian Lemke: Are there other systems that stand out?

Andreas Brandt: Another good example is our Side Seam Gluing Solution for folding carton production. It replaces the classical glue wheel still so common today in production lines. From the standpoint of sustainability, the glue wheel is a total nightmare that originated a long time ago. The conventional glue wheel requires extensive cleaning every single day. Unused adhesive has to be discarded and copious amounts of water are consumed for cleaning. In contrast, our solution is completely non-contacting and digital. That means no glue tank that gets soiled and has to be emptied and cleaned, no water for cleaning, no adhesive waste, no additional chemicals. And the effect goes beyond conserving resources: Less time for cleaning means more time in operation for the machines. In other words, greater efficiency coupled with a smaller ecological footprint. It’s a win for both the environment and cost-efficiency.

Florian Lemke: Is digitalization a factor here and in adhesive application in general?

Andreas Brandt: Yes it is, a major factor actually. You need precision data recording if you want to efficiently control a process. We offer systems that monitor and document adhesive consumption, temperature, application points, and more in real time. Information like this helps to control a process, but is also important for documentation and quality assurance, for instance in food packaging and pharmaceutical applications.

Florian Lemke: How would you describe the future of adhesive application in the packaging industry?

Andreas Brandt: I think we are at the very beginning of a development that is bringing sustainability, digitalization and automation closer together. As a systems supplier, it is our job to engineer solutions that merge these trends for the benefit of our customers and the environment.

Florian Lemke: Thanks for the in-depth discussion!

Andreas Brandt: My pleasure. I look forward to every opportunity to show that sustainable gluing is not a contradiction in terms, but an important issue that is relevant to the future of our industry.

Conclusion:

What may sound insignificant at first, harbours tremendous potential at second glance: Precise and economical adhesive application helps significantly to conserve resources in the packaging industry. With its technologies and durable components, Baumer hhs shows how sustainability can be achieved already today in production – not as a marketing cliché, but as a tried-and-tested, cost-efficient solution. Our interview with Andreas Brandt proves: Making production more sustainable means investing not necessarily more in new technologies, but more intelligently.