This, combined with the advent of other innovative packaging forms, has resulted in a surge in corrugated board and thicker cardboard packages. These packages are meticulously produced and glued using specialized machinery known as Specialty Folder Gluers or Multipoint Gluers.

Amazon, a global e-commerce giant, has been a significant driver of the trend in utilizing sale packaging as shipping packaging. While this trend has been contested for its potential lack of sustainability in certain scenarios, it has proven to contribute to enhanced sustainability in many instances. Particularly, when customers either place a single order or opt for regular product subscriptions. This trend, despite the surrounding discourse, presents an unavoidable challenge that the packaging industry must address.

Customers view : The Amazone survey

A recent survey conducted by OnePoll on behalf of Amazon unveiled that a considerable percentage (57 percent) of Germans are in favor of receiving their online orders without any additional shipping packaging, reflecting a heightened environmental consciousness.

The survey, which took responses from 2,000 adults, exhibits a growing trend in e-commerce shipping practices in ecommerce. Amazon, which commissioned the survey, has already been proactive in this regard, increasingly delivering everyday items like kitchen appliances, nappies, and washing powder to its German customers without additional packaging.

This move not only addresses consumer preferences but also aligns with Amazon´s broader global efforts to minimize waste and environmental impact. As one of the leading global ecommerce giants, Amazon's initiative sets a precedent for others in the industry to follow.

A large majority of customers expressed that the recyclability of the packaging material used for their orders is a matter of prime importance to them. This demonstrates a growing awareness and concern about the environmental impact of packaging waste, aligning with the global shift towards sustainable consumption.

"To Re-use or Recycle? A short Insightful Excursion into the ongoing debate"

Interestingly, the Amazon survey also found that only one in five customers, or 20%, attaches importance to the reusability of the packaging. This relatively lower interest in reusability may be attributed to factors such as convenience and practicality. While reusable packaging can help reduce waste, it often requires customers to take additional steps such as returning packaging materials for reuse.

The concept of reusable, yet ultimately disposable, plastic packaging being a more sustainable option than recyclable, fibre-based materials is also being challenged in politics. The member of the European Parliament Miapetra Kumpula-Natri (S&D, Finland) has highlighted this issue in an insightful article published in The Parliament Magazine. The argument put forth examines the long-term implications of plastic use, emphasizing that despite its reusability, plastic's eventual disposal poses significant environmental concerns https://www.theparliamentmagazine.eu/news/article/the-eus-packaging-reuse-targets-could-worsen-europes-water-scarcity).

The Crucial Role of Packaging Integrity in Business Success

Amazon places a high premium on ensuring the safety of products during transport. This is a critical aspect of their business operations as it directly impacts customer satisfaction and the overall reputation of the company.

As part of this commitment, Amazon requires that the safety of the product during transport must be guaranteed and demonstrably proven through a test. This test is designed to assess the basic suitability of the packaging used for shipping. This ensures that the product can withstand the rigors of transport, handling, and delivery without sustaining damage.

The packaging suitability for a specific shipping form not only requires an efficiently designed and certified model, but also necessitates rigorous monitoring of the production process to maintain the quality. Poor or defective packaging can cause severe damage or even loss of the product during transit. Such incidents not only affect customer satisfaction, but also tarnish the manufacturer's reputation. Therefore, the repercussions of inadequately designed or poorly produced packaging can be as detrimental to the business as an improperly designed product itself. Therefore, continuous monitoring and improvement in packaging design and production are essential for successful shipment and customer satisfaction.

End-to-end quality monitoring plays a critical role in ensuring sustainability. It is notable that the resources expended on the production of the actual product often surpass those used in its packaging. Consequently, damage to the product, whether due to inadequate glueing or other factors, signifies the wastage of all resources invested in its production. Therefore, implementing comprehensive quality control mechanisms from the initial stages of production to the final packaging is not just a matter of economic prudence, but also an imperative for sustainable resource management.

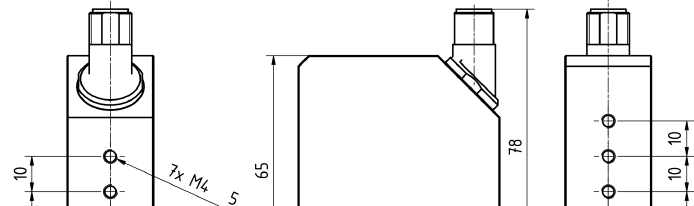

The landscape of monitoring in Multi-Point-Gluers has undergone a significant shift with the recent introduction of the ULT 400 XL sensor by Baumer hhs. This state-of-the-art sensor is designed to monitor adhesive application on a large reading distance, a feature that drastically revolutionizes the process and efficiency of multi-point gluing. In the past, the rigidity of corrugated boards posed a substantial risk of damage to the equipment due to its stiffness. This has been effectively mitigated with the ULT 400 XL sensor, which, with its large reading distance and exceptionally stable product guidance, eliminates this risk. The sensor's capacity to provide continuous monitoring even amidst fluctuating or fluttering substrates is a testament to its advanced design and technology. The large reading distance of the ULT 400 XL sensor is not only beneficial for avoiding equipment damage but also plays a pivotal role in enabling continuous monitoring. In scenarios where substrates are inconsistent or prone to fluctuations, traditional sensors might struggle to provide reliable readings. However, the ULT 400 XL sensor's ability to maintain stable readings over long distances ensures that monitoring can proceed without interruption or compromise.

The quality data accumulated during the adhesive monitoring process serves not only as a critical tool for maintaining operational efficiency, but also as a testament to your commitment towards delivering high-quality products to your customers. This data reflects the meticulous checks and balances your company employ in monitoring high quality adhesives application, ensuring that your common stringent quality standards are regularly met. By sharing this relevant information with your customers, concrete proof of the quality they can expect from your products can be provided. It builds customer trust, enhances transparency and ultimately strengthens your business relationships. Hence, adhesive monitoring data is not just a quality assurance tool, but also a powerful customer engagement asset.

We invite you to explore the innovative monitoring capabilities of our brand-new monitoring system for Multipoint Gluer and Specialty-Folder Gluer. Our worldwide sales staff is readily available to assist you with any queries or concerns. Don't hesitate to reach out to us for comprehensive information about these advanced monitoring solutions and their enhanced features.

Thomas Walther

Corporate Strategy & Innovation Baumer hhs

Preview photo: Amazon