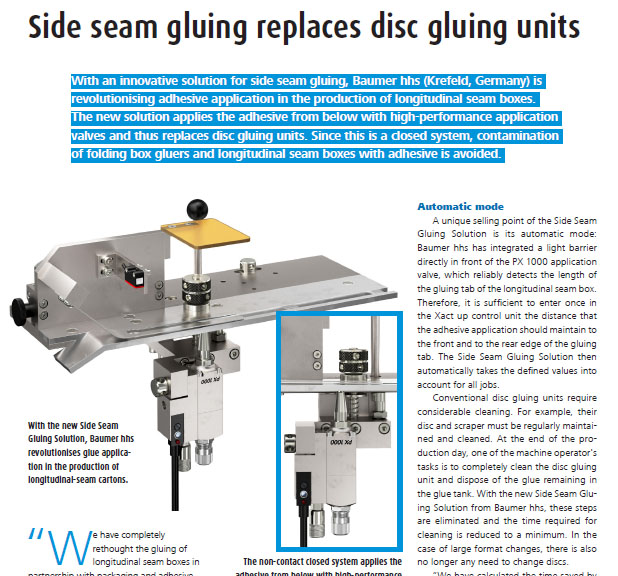

With an innovative solution for side seam gluing, Baumer hhs (Krefeld, Germany) is revolutionising adhesive application in the production of longitudinal seam boxes.

The new solution applies the adhesive from below with high-performance application valves and thus replaces disc gluing units. Since this is a closed system, contamination

of folding box gluers and longitudinal seam boxes with adhesive is avoided.

"We have completely rethought the gluing of longitudinal seam boxes in partnership with packaging and adhesive manufacturers. Our Side Seam Gluing Solution guarantees perfect and millimetreaccurate adhesive application right up to the edge of the gluing tab. At the same time, it is characterised by the simplest operation and adjustability, which raises the work

of the machine operator to a new level. In addition, adhesive consumption in the production of longitudinal-seam cartons can be significantly reduced thanks to the intelligence of our Xact up control unit, the performance of our PX 1000 application valve and the very precise pressure regulation of our DPP double-piston pump. At the same time, downtimes for disc changes are eliminated and the cleaning effort is reduced to a minimum. This greatly reduces the workload of machine operators,” says Ralf Scharf, Business Development Manager Folding Carton at Baumer hhs, listing the key advantages of the new Side Seam Gluing Solution. “Our customers who are already working with the new technology in practical operation confirm excellent results

in glue application – even at the highest machine speeds of up to 600m/min.”

Automatic mode

A unique selling point of the Side Seam Gluing Solution is its automatic mode:

Baumer hhs has integrated a light barrier directly in front of the PX 1000 application valve, which reliably detects the length of the gluing tab of the longitudinal seam box. Therefore, it is sufficient to enter once in the Xact up control unit the distance that the adhesive application should maintain to the front and to the rear edge of the gluing tab. The Side Seam Gluing Solution then automatically takes the defined values into account for all jobs. Conventional disc gluing units require considerable cleaning. For example, their disc and scraper must be regularly maintained and cleaned. At the end of the production day, one of the machine operator's tasks is to completely clean the disc gluing unit and dispose of the glue remaining in the glue tank. With the new Side Seam Gluing Solution from Baumer hhs, these steps are eliminated and the time required for cleaning is reduced to a minimum. In the case of large format changes, there is also no longer any need to change discs. “We have calculated the time saved by the elimination of cleaning alone, which is one of the elementary tasks of the machine operators in disc gluing plants: If we take 25 minutes of cleaning per shift as a basis, we come to an availability gain of about 200 hours per year per folding box gluing machine with a 2-shift operation and

250 working days. During this time, the machines can produce more than 20 million folding cartons,” says Scharf, calculating the gain in profitability. In addition, the Side Seam Gluing Solution enables significant savings in adhesive consumption, which not only benefits the economic efficiency of the process but also its sustainability. For example, the daily

cleaning of disc gluing units and the disposal of the remaining adhesive from the glue pots usually waste about three litres of adhesive each. Scharf: “With 250 working days a year and glue costs of around €2.50, this adds up to almost 2000 euros saved per year and folder-gluer. Combined with the elimination of cleaning times, investments in the Side Seam Gluing Solution alone pay for themselves in less than six months.”

Intelligent control

In the new solution for side seam gluing, the intelligent Xact up control unit, the high application quality of the PX 1000 valve, laser light barriers for reliable detection of the gluing tab and intelligent software algorithms play together perfectly. The PX 1000 is characterised by high closing force, which guarantees a perfect glue break and thus allows precise metering and

application of adhesive dots and areas. In many applications, this allows the adhesive application to be switched to Baumer hhs's Glue Save Mode (Stitching Mode). In this mode, the adhesive application is interrupted in a defined manner, which allows savings in adhesive consumption of up to 50%. At the same time, the adhesive strength is improved: “When applying

adhesive dots and short adhesive areas, a maximum force distribution is created in the adhesive. This prevents cohesive fractures. The quality of the bondings benefits from this,” Scharf explains the technical background. Two more aspects of how the Side Seam Gluing Solution improves sustainability in the production of longitudinal seam boxes: When conventional disc gluing units are cleaned, at least 30 litres of hand-hot water are used each time. From an ecological point of view, this no longer fits into today's world. In addition, the Baumer hhs adhesive application system is characterised by high energy efficiency. Another advantage of contactless adhesive application with the innovative solution from Baumer hhs is the closed continuous adhesive supply. The electronically controlled DPP double piston pump ensures that the appropriate adhesive pressure is provided at every production speed and thus the defined amount of adhesive is always applied to the glue tab. This guarantees consistent quality of the folding cartons produced.

Flexible and simple regulation of adhesive application

Scharf: “Our Side Seam Gluing Solution is based on the latest technology, which enables flexible and very simple regulation of the glue application on the gluing flap of longitudinal seam boxes with the best application quality. In addition, user-friendliness is significantly increased and adjustment times minimised, as the system recognises the lengths of the gluing flaps via the

light barriers and makes all the necessary adjustments. This virtually eliminates all arguments for disc gluing units.” The new Side Seam Gluing Solution can be used and retrofitted in any folding carton gluing machine. For quality control, packaging manufacturers can use the existing sensor technology that they have previously used in their disc gluing units.